View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Industrial |

| Click to view more | |

Product Details

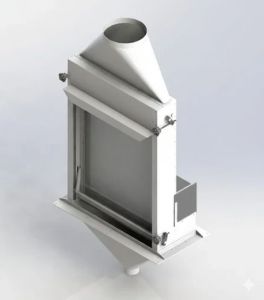

A screw feeder is a mechanical device used to transport materials, typically in a controlled manner, from one location to another. It is commonly used in industrial processes such as food processing, chemical production, and mining.

The screw feeder consists of a rotating screw or auger, which moves the material along a tube or trough. The screw is powered by an electric motor, and the speed and direction of rotation can be controlled to regulate the flow rate and direction of the material. The material is typically fed into the screw feeder from a hopper or other storage container.

Screw feeders can be designed to handle a wide range of materials, including powders, pellets, and granular materials. They are often used in conjunction with other equipment, such as a vibrating feeder or a hopper, to ensure a consistent and controlled flow of material.

Screw feeders can be used for a variety of purposes, including metering, blending, and conveying materials. They are also used in applications where precise control of material flow is required, such as in the production of pharmaceuticals or in the handling of hazardous materials.

Features :

Screw feeders can come with a variety of features depending on the specific application requirements. Some of the common features of screw feeders include:

- Type of Screw: Screw feeders can be designed with different types of screws, such as helicoid, sectional, ribbon, or paddle screws, to handle different types of materials.

- Hopper: A hopper is a container that holds the material to be fed. Screw feeders can be designed with different hopper sizes and configurations to meet the needs of specific applications.

- Feed Rate: Screw feeders can be designed to handle different feed rates, which is the amount of material that is dispensed per unit of time.

- Control System: Screw feeders can be equipped with a variety of control systems, including manual, automatic, and programmable logic controllers (PLCs). These control systems can help to regulate the flow of material and ensure consistent feeding.

- Material of Construction: Screw feeders can be made from different materials such as carbon steel, stainless steel, and plastic depending on the nature of the materials being fed and the environment in which the equipment will operate.

- Safety Features: Screw feeders can be designed with various safety features, such as guards, emergency stop buttons, and alarms, to protect operators and prevent accidents.

- Maintenance Features: Screw feeders can be designed to include features that make maintenance easier, such as easy access to components, quick-release mechanisms, and self-cleaning designs.

Overall, screw feeders can be customized to meet the specific needs of a wide range of industries and applications. By selecting the right features for your application, you can ensure reliable and efficient feeding of materials.

Looking for "Screw Feeder System" ?

Explore More Products